Faster and more economical production of large format graphics prints

Objective

- Expand the possibilities of professional commercial printing with new applications, save time, increase productivity and reduce the energy consumption of production machines.

Solution

- Implementation of modern large format graphics machines from Canon: Arizona 2380XTF and Colorado 1650.

Benefits

- Expansion of the portfolio of printing applications in connection with the use of low-temperature UVgel technology

- Achieve significant time savings by utilizing Arizona FLOW technology, which eliminates the labor-intensive process of masking

- Reduce production time for prints on soft substrates

- Reducing the energy consumption

- Immediate production of orders.

Challenges

- Variety of projects performed by the company

- Changing production capabilities to the changing market

- More and more orders with very short lead-times.

Flexibility and reliability

The P11 Group, which two decades ago started as a classic advertising agency, today is primarily a production company. In the modern hall, among others, commercial and store stands, displays or advertising walls are manufactured. Classical visual advertising still remains an important part of the business: posters, banners, signboards and pylons.

Thanks to its advanced fleet of modern equipment, the company is able to adapt quickly to market needs. The pandemic proved to be a direct test – they switched machines and started mass production of visors and virus shields almost overnight.

This proves that flexibility in business is indispensable. Readiness for sudden changes allowed us not only to survive the difficult months for the industry, but also to develop our current activity and skills – comments Artur Łagodziński.

Time-saving technologies

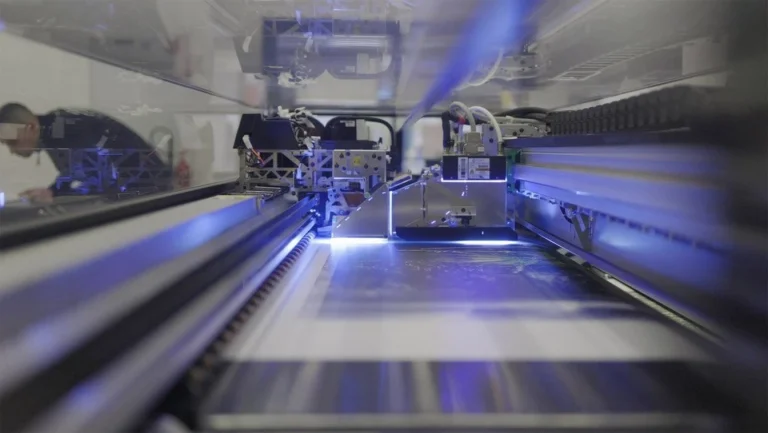

One of the most essential devices in the daily work of the company are the Canon Arizona and Colorado systems. They are the real printing locomotives of P11 Group. Both are equipped with innovative technologies, providing faster and more durable printing on various types of substrates.

The Arizona 2300 series can print on hard surfaces such as plastic, plexiglass, dibond, wood and glass. It also offers the Arizona FLOW airflow technology which, combined with a zone-free table layout, means less masking and easy job changeover. A pneumatic pin set allows for instant substrate positioning on the table. Once the substrate is quickly mounted, the machine delivers efficient and precise printing on both sides of the substrate.

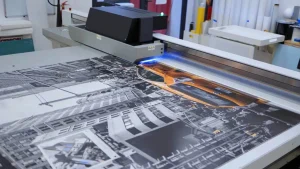

On the other hand, the ultra-modern Colorado 1650 is capable of printing on various types of soft substrates. Its special features include flexible UV inks, a matte or glossy finish and two automatic media rolls. And most importantly, it has a low-temperature curing technology that allows you to print on a wide range of substrates, including those sensitive to high temperatures, without worrying about material deformation. Prints made with the Colorado 1650 are immediately dry and ready to hand to the customer, which significantly shortens the production process.

Support for good ideas

For the P11 team, it is extremely important to minimize the impact of their daily work on the surrounding environment. That’s why Arizona and Colorado’s work is supported by a state-of-the-art Zünd cutting system – it not only helps to simplify and speed up finishing work, but also to minimize unnecessary waste.

P11 also chose Canon because they wanted production machines with low energy consumption. To power them, it uses photovoltaic panels, which were installed on the roof.