The Norwegian production companies are definitely in the forefront both technologically and market-wise, Canon’s European product manager, Stefanie Schumann, concluded when she recently visited Norwegian Arizona customers.

Close contact with the market

The lines of communication between the product managers in Norway and Canon’s Dutch Large Format center in Venlo have always been short and direct, it is part of Canon’s culture. And both Stefanie Schumann and her Norwegian colleagues Henning Hagelund and Anton Strand have been in the industry for over 20 years, so they know each other well. There were therefore no big surprises that met the European product manager when she joined Henning and Anton for the Norwegian production companies Sign Production, Pulp Grafisk, i-Pack Digital and Reklame Service. – From Venlo, we have weekly updates with the Norwegian product managers, where we share useful information about customers, investments, business areas and markets. Still, it’s something else to visit the companies than to hear about them, for those who work in production always has wishes and needs that we immediately pass on to our R&D people, says Stefanie Schumann.

Strong desire for automation

A busy round of visits in minus degrees in Eastern Norway confirms the feedback the product manager receives from similar production companies in other countries, namely a strong desire for the highest possible degree of automation and a seamless interaction between technological solutions from different manufacturers. – The production companies’ everyday life is that customers want digital communication lines and that more and more assignments are to be delivered in less time than before, a situation that has been further strengthened during the COVID period. Therefore, it is also natural that our customers want to automate where possible. It is the backdrop that automation is the key word for what is going on in Canon’s R & D department, both in terms of our own solutions and for the important collaboration we have with our many technology partners, she emphasizes.

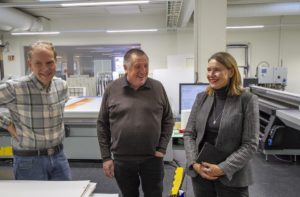

Stefanie Schumann visited Norwegian production companies, and received useful input from, among others, Pulp Grafisk

The technology partners play a crucial role

So technology partners are playing an even more important role than before? – Undoubtedly, there are many smart solutions that will talk to our systems and to each other, and it requires a lot of software adaptations and collaboration, Stefanie Schumann answers. And if you are in doubt, the robots are already in the process of graphic production.– The use of robots is most relevant when the assignments are large and homogeneous. For example, a Dutch manufacturing company already uses robots to move and handle the materials in and out of the Arizona board. In that area, we work closely with the technology partner who adapts and programs the company’s two robots, so that the robot, for example, knows when the material has been printed. For other customers with greater variation in the assignments, robots are not as relevant, but we have partners in a number of other areas, so that the customer gets the maximum return on investment. Here in Norway, we see that many want to be at the forefront of automation, for example Sign Production is a good example of this, she says.

Versatile production at Pulp Grafisk, as you can see from the exhibition here.

Danish technology partner underway

At Pulp, they have invested heavily in recent years, and with three Arizona machines and two Colorado machines, automatic cutting tables with “Eye-in-the-sky” for automatic monitoring, you might think there are not many areas where you can save time and costs. But maybe there are some anyway, because Erling Lindboe at Pulp is happy to admit that the company could have wished for an even more streamlined system for production management and logistics. Then it is probably good news that one of Canon’s newest technology partners is Danish Captor, a software company that works closely with Canon on the development of an order / logistics system tailored for precisely large-format graphic production. – It will be a module-based system, so that you can start up at a simple level and expand gradually. This is undoubtedly an advantage in Scandinavia, where many of the production companies are smaller companies. Maybe we have the first installation in this country already in the first quarter of next year, reveals two good colleagues over many years; Henning Hagelund and Stefanie Schumann.

At Pulp, they have three different Arizona printers and a Zund cutting table. Stefanie Schumann takes all input from the customer back to Canon’s R&D department in the Netherlands.

Published 08th Dec 2021